How Fuji Gemco’s PLC Automation Enhances Industrial Safety

The industrial sector is the backbone of manufacturing economies, but is also inherently risky. From high-voltage equipment to complex mechanical systems and volatile processes, ensuring safety is more than a regulatory requirement—it is a business-critical priority. For companies aiming to grow sustainably while protecting their employees and assets, investing in intelligent safety systems is no longer optional.

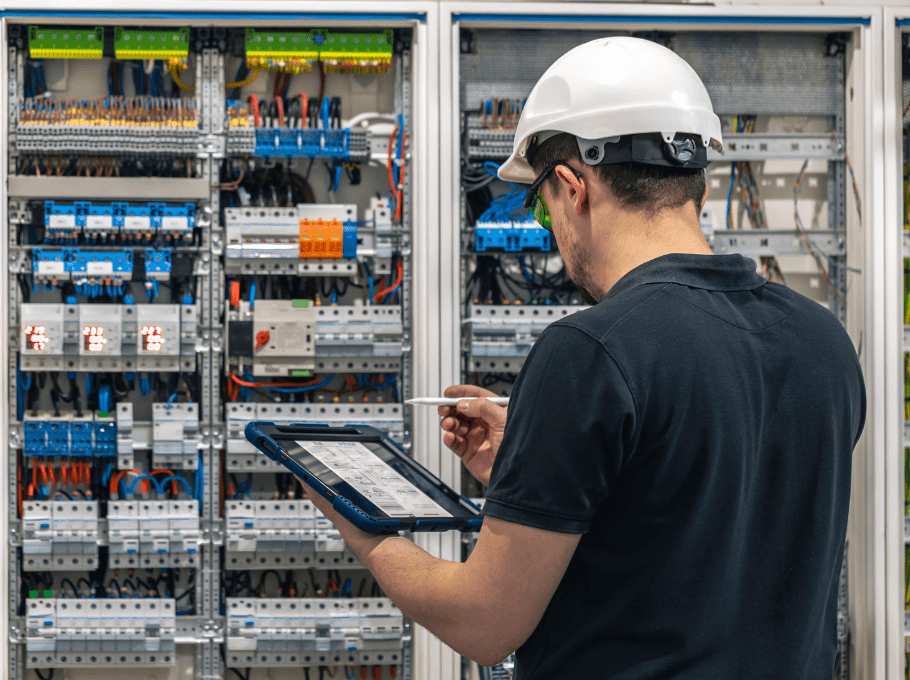

Fuji Gemco, a joint venture between Fuji Electric (Japan) and Gemco Controls (India), is a leading supplier of PLC automation systems. With decades of expertise across industries such as hot rolling mills, cold rolling mills, sugar plants, paper mills, and power distribution systems, Fuji Gemco delivers state-of-the-art systems that enhance performance, improve product quality, and minimize downtime.

What is PLC Automation and How Does it Affect Production?

A Programmable Logic Controller (PLC) is a rugged industrial computer used to automate and control manufacturing processes. These systems manage machinery, monitor sensors, and execute commands with speed and precision.

4 Ways Fuji Gemco’s PLC Automation Enhances Safety

- Emergency Stop Integration: PLCs are seamlessly integrated with emergency stop (E-stop) systems. In the event of a fault, E-stops can shut down the entire plant within milliseconds, preventing equipment damage and potential injuries.

- Real-time Monitoring & Alerts: Sensors connected to the PLC continuously monitor parameters like temperature, pressure, and flow. If thresholds are exceeded, the system sends alerts and initiates automated corrective actions to avoid escalation.

- Remote Diagnostics: Fuji Gemco’s systems allow remote troubleshooting and diagnostics, reducing the need for physical inspections and minimizing exposure to hazardous areas.

- Fail-safe Design: Redundant hardware and control logic ensure that systems operate reliably, even during component failures, thereby maintaining safety and uptime.

3 Reasons PLC Automation Reduces Human Error

- Programmed Consistency: Automated logic-based decisions remove the risk of manual misjudgment or inconsistency.

- Alert Fatigue Prevention: PLC systems trigger visual and auditory alarms, helping operators remain attentive to critical warnings.

- Digital Logs: All operations and alarms are digitally logged, enabling audits, root cause analysis, and operator training to prevent recurring mistakes.

Safety Standards and Compliance

Fuji Gemco’s PLC systems are designed to meet stringent international safety standards, including:

- IEC 61508: Functional Safety of Electrical/Electronic/Programmable Systems

- ISO 13849: Safety of Machinery — Safety-related Parts of Control Systems

These standards mandate risk assessments, redundancy in safety circuits, and proven design reliability—all built into Fuji Gemco’s automation architecture.

7 Features That Make Fuji Gemco a Trusted PLC Automation Supplier

- Intuitive HMI panels with real-time data visualization

- Modular PLC architecture for scalable upgrades

- Built-in diagnostics enabling predictive maintenance

- Event-driven alarms instead of time-based triggers

- Industry-specific customizable logic libraries

- Simulation and training support for operators

- 24/7 service assistance with reliable spare parts availability

Safety isn’t a Cost – It’s an Investment

In fast-paced industrial environments, the financial impact of accidents and downtime can be significant. The advantages of PLC automation are clear—from minimizing equipment failures and human error to improving safety and operational efficiency.

At Fuji Gemco, we believe that safety and productivity go hand in hand. Let our team help you modernize your operations with robust and reliable PLC automation solutions tailored to your needs.

Contact us to learn how we can enhance your plant’s safety and performance.

Visit Fuji Gemco’s website or call our experts for a consultation.